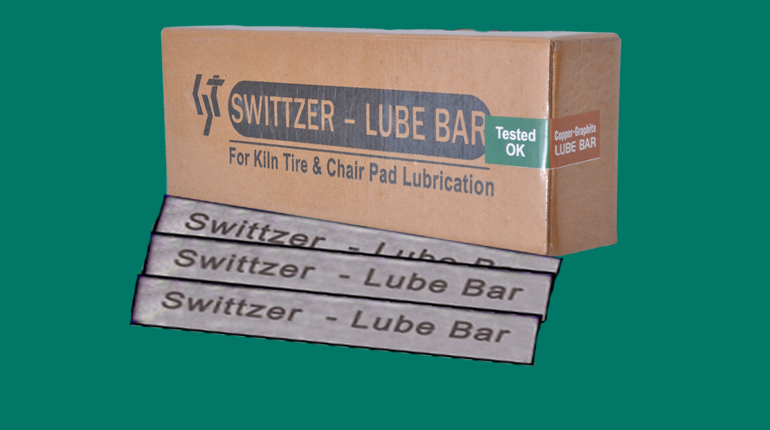

Swittzer Technologies Inc – An ISO 9001-2015 Certified company. Manufacturer of LUBE BAR’S in India Since-2004.

Swittzer Technologies Inc is largest manufacturer of LUBE BAR in South Asia for Rotary Kilns & Dryers Lubrication to reduce friction and wear for Cement, Mineral & Paper Industries.

SWITTZER - LUBE BAR rotary kiln Lube consists of a special high temp auto - ignition point synthetic thickener with organic and metallic solid film -forming components.

SWITTZER - LUBE BAR rotary kiln Lube deposits its solid film forming components into the surFace of the filler bars and ring bore to assure maximum protection from cold welding or galling in an easy to apply form for this severe high temperature application.

The Problem: Costly Kiln Maintenance-Swittzer Technologies Inc. - Recognizes that one of the largest threats to your business's production time is undoubtedly kiln downtime. The structure of a kiln contains a kiln shell, kiln tires, and tire support pads, it is inevitable that the kiln tires will move respective to the shell as the kiln rotates during operation. If the plane of the tire does not sit perpendicular to the kiln's rotating axis, the tire's rotation will slightly differ from the shell's rotation.

This circumstance can ultimately initiate:

High tire clearance and creep

High shell ovality

Kiln support wear

Tire bore wear

Refractory failures that result in high kiln maintenance costs and lost production time

ECO Friendly formulations

Lube Bar has No Hazardous Ingredient’s

The Solution: Swittzer Technologies Inc. – Lube Bar for Predictive Kiln Maintenance Luckily, you can utilize the power of predictive kiln maintenance to protect your kilns from unnecessary wear and tear. Swittzer – Lube Bar Kiln Tire Lubricant is a specially formulated blend of Graphite, Copper flakes and Soft metal powders enclosed within a natural carrier. When applied to your kiln, Swittzer – Lube Bar dissipates into your kiln, simultaneously lubricating both the support pad outside diameter and the kiln tire internal diameter. This in turn:

Helps Reduce

minimizes friction across the support pads

decreases Tire retainer pressure

Diminishes the effects of tire bore and support pad wear

Discourages overall kiln support wear

Swittzer – Lube Bar is the absolute most economical lubricant available on the market today. It is also the only dissipating lubricant bar for kiln predictive maintenance that does not contain any hazardous ingredients. Therefore, it does not emit any hazardous gases throughout your facility as you lubricate your kilns with the product.

| TYPICAL PROPERTIES | |

|---|---|

| Class of Product | Labe Bar (Copper Graphite & Soft Metal Enclosed) |

| Solid Content | 38-44% Typical |

| Melting Point | 132°F - 140°F (55° - 60° C) |

| Auto Ignition Point | 955°F (512° C) |

| Physical Texture | Compact Smooth |

| Cone Penetration for Base @ 80°F | 13 Max |

| Flash Point (COC) | 415°F (212° C) |

| Physically in colour | Brown |

| Hazardious Ingredients | NIL |